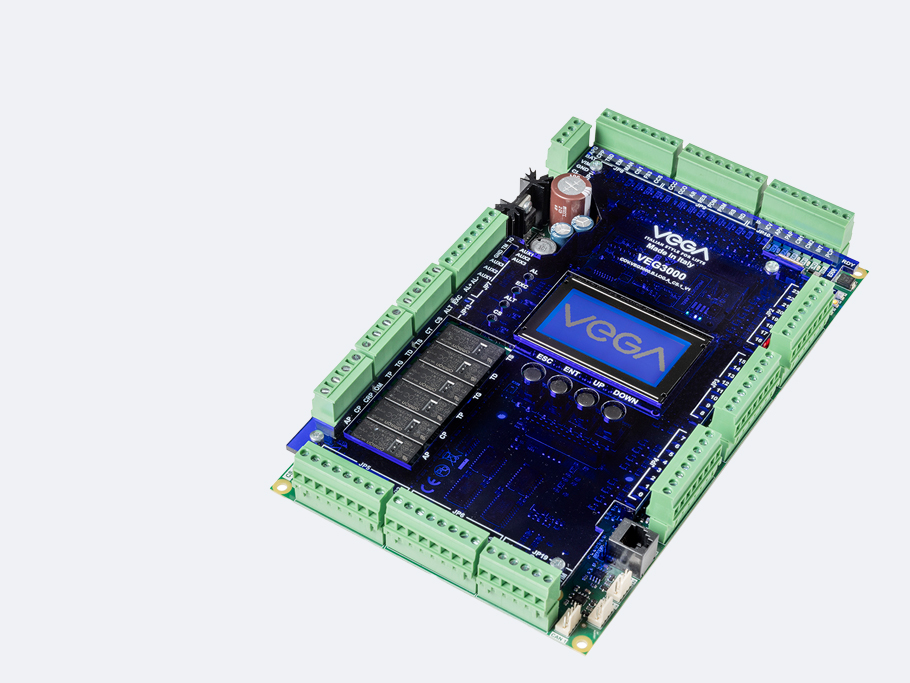

Parallel and serial control board with graphic display

VEG3000

CONTROL / Placas de maniobras

MAX NUMBER OF STOPS: up to 24 by parallel connection, up to 32 by serial connection.

MAX NUMBER OF STOPS: up to 24 by parallel connection, up to 32 by serial connection. LIFT TYPE: hydraulic and traction lifts/homelifts.

LIFT TYPE: hydraulic and traction lifts/homelifts. SPEED: up to 4 m/s.

SPEED: up to 4 m/s. MULTIPLEX MANAGEMENT: up to 8 lifts in the same group connected through CAN-BUS and WITHOUT additional expansions.

MULTIPLEX MANAGEMENT: up to 8 lifts in the same group connected through CAN-BUS and WITHOUT additional expansions. PROTOCOLS: 2 “VEGA serial” channels, 1 “CAN-BUS” channel.

PROTOCOLS: 2 “VEGA serial” channels, 1 “CAN-BUS” channel. CAR POSITIONING: by using magnetic sensors and absolute encoder CAN-BUS without additional expansion boards. By incremental encoder with additional expansion board.

CAR POSITIONING: by using magnetic sensors and absolute encoder CAN-BUS without additional expansion boards. By incremental encoder with additional expansion board.

— Lift operations types – Hold-to-Run, 1 single call plant, collective.

— Keypad – Fixed with graphic display (128×64 pixel).

— Diagnostic – LEDs on board. Messages on display for error alerts and board status and clock.

— FW update – By USB.

— Programming – By local keypad, by PC both in local and remote.

— Remote monitoring – With Vega Cloud system via GSM data.

— VVVF Management – By digital or analog commands (additional expansion needed).

— Dimensions: 150×255 mm.

— Power supply: 24Vdc +/- 10%.

— Battery charger: integrated, 12Vdc (automatic disconnection of the battery in case of turning off), stabilized 12V auxiliary output, available even in case of power failure.

— Safeties management: 3 inputs manageable from 24V to 110V AC/DC + 4° optional input manageable from 12V to 48V AC/DC.

Aplicación de control de instalaciones

— User-friendly programming interface.

— Bluetooth connection.

— Reading/writing parameters and faults monitoring for Vega Control boards.

— Reading/writing parameters and faults monitoring for Vega door drives.

ManagerLift allows you to remotely manage homelifts and elevators with just one click.

And the good news is: no dedicated software to download. Visit www.managerlift.com.

Conexión a tierra

¿Has optado por instalar los productos electrónicos de Vega en una placa metálica?

Atención: conecta las placas al sistema de toma de tierra. De este modo, evitarás posibles fallos de funcionamiento o daños en los dispositivos electrónicos.

Limpieza del producto

¿Cómo limpiar los pulsadores de Vega? Con un paño de algodón y agua caliente.

Precaución: no utilizar productos químicos, especialmente para las superficies de plástico. Muchos productos de Vega están fabricados en policarbonato, ABS, metacrilato o nailon 66. Evita los productos de limpieza que contengan (incluso en pequeña cantidad) amoniaco, hidrocarburos, sosa cáustica, ácido clorhídrico, ácido nítrico, ácido acético, alcohol etílico, alcohol metílico.